Hexa-Cover is the ideal solution for eliminating such things as:

Hexa-Cover Floating Cover ensures:

Hexacover is not only a very effective water preservation product, it is also very easy to install with no repair or maintenance costs.

Hexacover has been trialed by the Western Australia Government recording a reduction in evaporation of 73%, saving more than 1.6 million litres of drinking water across 3 dams.

Talk to one of our team today for more information.

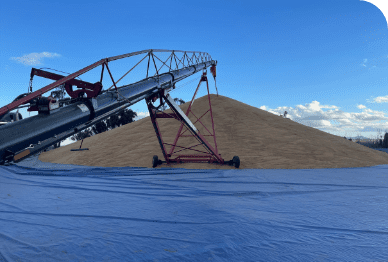

Polytex Bunker Covers or Bunker Tarps can include tarp stenciling to your specifications

Polytex has a vast network of recommended & competent carriers Australia wide.

Polytex uses only first quality industrial fabrics for the manufacture of all products; well-known brands including Canvacon, Tarpee & Landmark variations

Access our calculator to get a comprehensive guide to planning and designing your grain storage.