Home / Shop / Produce & Commodity Protection / Grain Protection / Grain Bunker Covers

Grain Bunker Covers have many advantages over other storage methods such as steel silos, bags, or sheds. Some of the benefits of using grain bunker tarps are:

• Affordable and cost-effective. Grain Bunker Tarps are the most cost-effective method of storing over 1000T of grain.

• Flexible and adaptable. Can be set up on-farm with good drainage and access, and can easily be expanded.

• Safe and secure. Protect your grain from the sun, rain, wind, and pests. Our Grain Bunker Covers also allow for effective fumigation and aeration to maintain optimal grain conditions.

• Reduce the storage losses and wastage of grain due to weather, pests, or theft.

• Improve the quality and value of grain by preserving its moisture, temperature, and freshness.

• Enhance the profitability and competitiveness of the grain industry by allowing for better market timing and price optimisation.

• Support the food security and sustainability of the country by ensuring adequate supply and availability of grain.

* PE [Polyethylene]

* PP [Polypropylene]

* PVC [Poly Vinyl Chloride]

$5,632.00 – $9,920.00

Are you looking for a reliable and cost-effective way to protect your grain from the elements? Do you want to store your grain on-farm without compromising its quality and value? If so, you need Grain Bunker Covers or Grain Bunker Tarps from Polytex.

Polytex is a major supplier of grain bunker covers, grain bunker tarps, grain harvest covers and ground sheets for both grain dealers and grain growers alike. We have the capacity to produce a large number of grain bunker covers or grain bunker tarps promptly and arrange for quick delivery anywhere in Australia.

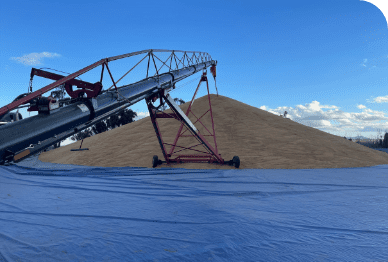

Grain Bunker Covers are temporary storage solutions for your grain. They are made from premium quality fabrics that are durable, UV-resistant, waterproof, and pest-proof. They are designed to fit any size and shape of the bunker and can be easily installed and removed.

Grain Bunker Tarps, or Grain Bunker Covers, consist of two parts: a bottom sheet that lines the bunker floor and walls, and a top sheet that covers the grain stack. The grain bunker tarp is then sealed to create an airtight environment for fumigation to preserve the grain quality and prevent moisture, insects, rodents, and birds from entering.

Grain Bunker Covers have many advantages over other storage methods such as steel silos, bags, or sheds. Some of the benefits of using grain bunker tarps are:

• Affordable and cost-effective. Grain Bunker Tarps are the most cost-effective method of storing over 1000T of grain.

• Flexible and adaptable. Can be set up on-farm with good drainage and access, and can easily be expanded.

• Safe and secure. Protect your grain from the sun, rain, wind, and pests. Our Grain Bunker Covers also allow for effective fumigation and aeration to maintain optimal grain conditions.

• Reduce the storage losses and wastage of grain due to weather, pests, or theft.

• Improve the quality and value of grain by preserving its moisture, temperature, and freshness.

• Enhance the profitability and competitiveness of the grain industry by allowing for better market timing and price optimisation.

• Support the food security and sustainability of the country by ensuring adequate supply and availability of grain.

* PE [Polyethylene]

* PP [Polypropylene]

* PVC [Poly Vinyl Chloride]

Polytex Bunker Covers or Bunker Tarps can include tarp stenciling to your specifications

Polytex has a vast network of recommended & competent carriers Australia wide.

Polytex uses only first quality industrial fabrics for the manufacture of all products; well-known brands including Canvacon, Tarpee & Landmark variations

Access our calculator to get a comprehensive guide to planning and designing your grain storage.