Home / Shop / Produce & Commodity Protection / Grain Protection / Grain Bags

A grain storage bag can offer many benefits for growers, but there are also potential risks and challenges associated with their use. It’s important to be aware of these risks to mitigate them effectively. Some potential risks include:

Moisture Ingress: Even though a grain bag is designed to be airtight, there is still a risk of moisture entering the bags, especially if they are not sealed properly or if there are tears or punctures in the material. Moisture ingress can lead to mould growth, spoilage and a decrease in grain quality.

Pest Infestations: Stored grain may still be vulnerable to pest infestations if the bags are not sealed properly or if pests manage to breach the bag’s defences. Insects and rodents can cause significant damage to stored grain. The best way to minimise this risk is to ensure good hygiene around the bags, i.e. no spilt grain or food that would attract pests and rodents.

Temperature Fluctuations: While grain storage bags can provide some insulation against temperature fluctuations, extreme temperature changes can still affect the internal environment of the bags. Rapid temperature shifts can cause condensation, leading to moisture buildup and potential spoilage.

Bag Strength: The quality of the material and construction of the grain bag is crucial. If the bags are made from inferior materials or are not properly constructed, they may be more prone to tears, punctures, or seam failures. This can compromise the integrity of the storage environment.

Handling and Loading Challenges: Filling grain bags requires proper equipment and techniques to ensure uniform loading and minimal stress on the bag material. Inadequate handling practices can lead to bag ruptures, uneven loading, and inefficiencies.

Long-Term Storage Considerations: While grain storage in bags can be a useful short- to medium-term storage solution, they are not recommended for long-term storage due to the potential degradation of the bag material over time.

To mitigate these risks, it’s important for growers to carefully follow manufacturer guidelines for bag usage, sealing, loading, and unloading. Regular inspection of the bags for signs of damage or compromise is crucial. Additionally, implementing integrated pest management strategies and proper site selection can help minimise the risks associated with moisture, pests and other environmental factors.

Pros:

Cost-Effective: They are often more cost-effective than building permanent storage structures like silos. This can be beneficial for growers with limited budgets or temporary storage needs.

Flexible Storage: They offer flexibility in terms of capacity. It can accommodate varying quantities of grain, making it suitable as a backup storage option for high-yielding harvests.

Quick Setup: It is relatively quick to put together a grain bag compared to constructing traditional storage facilities. This can be useful during peak harvest times when the need for storage space is urgent.

Space Efficiency: A grain bag utilises available space efficiently, as it can be placed in locations where traditional structures might not be feasible. They can also be a handy option for collecting grain directly from the chaser bin and storing it at a central site on the farm.

Reduced Capital Investment: Using these bags eliminates the need for significant upfront investments in permanent storage structures. This allows growers to allocate resources to other areas of their operation.

Cons:

Risk of Damage: Grain bags are vulnerable to damage from rodents, birds, pests and even machinery during loading and unloading. Proper sealing, handling and good site hygiene are essential to prevent these issues.

Limited Long-Term Storage: For long-term storage, they are not the best option due to the potential degradation of the bag material over time and can pose grain quality risks.

Moisture Management: Although grain bags are designed to be airtight, proper moisture management is essential to prevent mould, fungal growth and spoilage within the bags. It is recommended to conduct sampling and regular checks.

Quality Control Challenges: Monitoring and maintaining grain quality within bags can be more challenging compared to traditional storage facilities that offer better ventilation and control.

Labour and Equipment: Loading and unloading grain storage bags require specific equipment and labour. Improper loading techniques can lead to uneven settling and air pockets within the grain.

Overall, grain bags offer flexibility and cost savings, particularly for short-term storage needs. However, they have their own set of challenges related to potential damage, proper sealing, moisture management and quality control. Growers should carefully consider their specific storage requirements and weigh the pros and cons before deciding whether it is the right choice for their operation.

The advantage of using a grain bag is the flexibility of where it can be stored. You can store them anywhere on your farm on clean firm ground, well-drained and free of sharp objects. Also, avoid placing them near trees. Having this flexibility can be handy during peak harvest to have central locations on the farm to reduce the time it takes chaser bins to empty and return.

Step 1: Choose a site for Grain Bag Management

Choosing an appropriate site is the first and most fundamental step in successful grain storage and management. This could mean placing bags in different paddocks or having a common central storage area for bags. The site needs to be chosen based on the different factors including easy filling, bag maintenance and monitoring, areas that allow machinery access and where water can be easily drained away.

Step 2: Prepare the site

This step includes clearing the soil and making it firm enough to prevent water pooling. It’s important to set up the site away from anything that can puncture the bag like sticks, rocks or sharp objects and away from sand hills or long grass where rodents shelter.

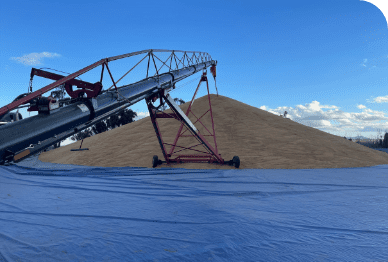

Step 3: Set up the Filling Machine

Make sure the machine is clean before filling the bags as grain pests, can survive in small amounts of grain left in equipment from the previous season. These pests can infest the new season’s grain and spread through the entire grain bag.

When setting up the bag on the filling machine, ensure the stretch markers are on a side where they can be seen and measured when the bag is filling.

Step 4: Fill the Bag

With patience and accuracy followed during filling, it will make emptying the bag much easier, reduce maintenance during the storage period and result in fewer spills and stops to realign machinery. It is important to keep the grain bag filling evenly and straight to avoid creases as mice tend to attack creases.

Step 5: Site Security and Maintenance

It’s essential to clean the site after filling to remove harbours for insects but will also remove feed that attracts mice and wildlife. Keep the site free of grass by spraying it regularly. Installing a sturdy fence may also prevent animals from accessing the bags.

During normal conditions check at least weekly. During wet weather, checking twice daily may be required if vermin are plentiful.

Step 6: Emptying Grain Bags

When making the initial cut in the bag for out-loading, place a piece of tape horizontally across the bag below where it is stretched tight at the top. Make the first cut perpendicular to the bag to avoid splitting up the entire length of the bag and exposing the grain.

Step 7: Clean up

Site clean-up is vital for success. Spilt piles of grain and leftover small bags of grain provide an ideal harbour for insects to live and breed. It’s crucial to clean grain residues from machinery used for grain handling to prevent reinfestation with insects or pests before the next season.

(Sourced from GRDC Grain Storage Fact Sheet. To read more visit www.storedgrain.com.au)

$1,215.00 – $2,750.00

WATCH: Northern Victoria Grain Grower, Jack Gall, shares his experience with Grain Bags and Grain Bunkers

Grain bags, also known as silo bags, can be a cost-effective option for growers storing grain temporarily to support harvest logistics. This also allows them access to higher-value marketing opportunities post-harvest.

Construction: Polytex’s grain bags are made to a high standard from polyethylene through a three-layer co-extrusion process, to a thickness of 250 microns. The layers are melted, creating a uniform film, inseparable and with great resistance. The outer white layer contains heat-resistant resins and UV stabilisers to protect against harsh UV and heat conditions. The inner layer has a high concentration of carbon black and is designed to keep out the sunlight. This process provides important properties required in a grain bag such as perforation resistance, thermal resistance, good stretching, internal temperature stability, reflection of solar rays and flexibility.

Quality: Our grain storage bags are imported from a well-known and recognised company in Argentina that manufactures premium grain bags and exports to more than 40 countries.

These bags have a proven track record in the Australian climate for over 7 years, therefore you can be assured of premium quality where it matters the most; protecting your investment.

While the bags are a cost-effective and quick option, they come with significant risks especially if you haven’t had previous experience. Site planning and preparation is the first and most critical step for successful storage. We have outlined the basic risks in the accordions below. However, if you are new to using this product we recommend talking to an expert or grower with previous experience.

Grain bunkers are an alternative option for storing grain with fewer risks and the ability to store longer-term. They have a slightly higher cost per tonne and require more preparation, and they can be used over multiple seasons.

A grain bag is ideal as a quick backup storage solution and with good preparation, sampling and regular checks can be an effective option.

Capacity: Polytex offers different sizes from 60 meters to 150 meters long, providing storage for 200T – 550T of grain.

A grain storage bag can offer many benefits for growers, but there are also potential risks and challenges associated with their use. It’s important to be aware of these risks to mitigate them effectively. Some potential risks include:

Moisture Ingress: Even though a grain bag is designed to be airtight, there is still a risk of moisture entering the bags, especially if they are not sealed properly or if there are tears or punctures in the material. Moisture ingress can lead to mould growth, spoilage and a decrease in grain quality.

Pest Infestations: Stored grain may still be vulnerable to pest infestations if the bags are not sealed properly or if pests manage to breach the bag’s defences. Insects and rodents can cause significant damage to stored grain. The best way to minimise this risk is to ensure good hygiene around the bags, i.e. no spilt grain or food that would attract pests and rodents.

Temperature Fluctuations: While grain storage bags can provide some insulation against temperature fluctuations, extreme temperature changes can still affect the internal environment of the bags. Rapid temperature shifts can cause condensation, leading to moisture buildup and potential spoilage.

Bag Strength: The quality of the material and construction of the grain bag is crucial. If the bags are made from inferior materials or are not properly constructed, they may be more prone to tears, punctures, or seam failures. This can compromise the integrity of the storage environment.

Handling and Loading Challenges: Filling grain bags requires proper equipment and techniques to ensure uniform loading and minimal stress on the bag material. Inadequate handling practices can lead to bag ruptures, uneven loading, and inefficiencies.

Long-Term Storage Considerations: While grain storage in bags can be a useful short- to medium-term storage solution, they are not recommended for long-term storage due to the potential degradation of the bag material over time.

To mitigate these risks, it’s important for growers to carefully follow manufacturer guidelines for bag usage, sealing, loading, and unloading. Regular inspection of the bags for signs of damage or compromise is crucial. Additionally, implementing integrated pest management strategies and proper site selection can help minimise the risks associated with moisture, pests and other environmental factors.

Pros:

Cost-Effective: They are often more cost-effective than building permanent storage structures like silos. This can be beneficial for growers with limited budgets or temporary storage needs.

Flexible Storage: They offer flexibility in terms of capacity. It can accommodate varying quantities of grain, making it suitable as a backup storage option for high-yielding harvests.

Quick Setup: It is relatively quick to put together a grain bag compared to constructing traditional storage facilities. This can be useful during peak harvest times when the need for storage space is urgent.

Space Efficiency: A grain bag utilises available space efficiently, as it can be placed in locations where traditional structures might not be feasible. They can also be a handy option for collecting grain directly from the chaser bin and storing it at a central site on the farm.

Reduced Capital Investment: Using these bags eliminates the need for significant upfront investments in permanent storage structures. This allows growers to allocate resources to other areas of their operation.

Cons:

Risk of Damage: Grain bags are vulnerable to damage from rodents, birds, pests and even machinery during loading and unloading. Proper sealing, handling and good site hygiene are essential to prevent these issues.

Limited Long-Term Storage: For long-term storage, they are not the best option due to the potential degradation of the bag material over time and can pose grain quality risks.

Moisture Management: Although grain bags are designed to be airtight, proper moisture management is essential to prevent mould, fungal growth and spoilage within the bags. It is recommended to conduct sampling and regular checks.

Quality Control Challenges: Monitoring and maintaining grain quality within bags can be more challenging compared to traditional storage facilities that offer better ventilation and control.

Labour and Equipment: Loading and unloading grain storage bags require specific equipment and labour. Improper loading techniques can lead to uneven settling and air pockets within the grain.

Overall, grain bags offer flexibility and cost savings, particularly for short-term storage needs. However, they have their own set of challenges related to potential damage, proper sealing, moisture management and quality control. Growers should carefully consider their specific storage requirements and weigh the pros and cons before deciding whether it is the right choice for their operation.

The advantage of using a grain bag is the flexibility of where it can be stored. You can store them anywhere on your farm on clean firm ground, well-drained and free of sharp objects. Also, avoid placing them near trees. Having this flexibility can be handy during peak harvest to have central locations on the farm to reduce the time it takes chaser bins to empty and return.

Step 1: Choose a site for Grain Bag Management

Choosing an appropriate site is the first and most fundamental step in successful grain storage and management. This could mean placing bags in different paddocks or having a common central storage area for bags. The site needs to be chosen based on the different factors including easy filling, bag maintenance and monitoring, areas that allow machinery access and where water can be easily drained away.

Step 2: Prepare the site

This step includes clearing the soil and making it firm enough to prevent water pooling. It’s important to set up the site away from anything that can puncture the bag like sticks, rocks or sharp objects and away from sand hills or long grass where rodents shelter.

Step 3: Set up the Filling Machine

Make sure the machine is clean before filling the bags as grain pests, can survive in small amounts of grain left in equipment from the previous season. These pests can infest the new season’s grain and spread through the entire grain bag.

When setting up the bag on the filling machine, ensure the stretch markers are on a side where they can be seen and measured when the bag is filling.

Step 4: Fill the Bag

With patience and accuracy followed during filling, it will make emptying the bag much easier, reduce maintenance during the storage period and result in fewer spills and stops to realign machinery. It is important to keep the grain bag filling evenly and straight to avoid creases as mice tend to attack creases.

Step 5: Site Security and Maintenance

It’s essential to clean the site after filling to remove harbours for insects but will also remove feed that attracts mice and wildlife. Keep the site free of grass by spraying it regularly. Installing a sturdy fence may also prevent animals from accessing the bags.

During normal conditions check at least weekly. During wet weather, checking twice daily may be required if vermin are plentiful.

Step 6: Emptying Grain Bags

When making the initial cut in the bag for out-loading, place a piece of tape horizontally across the bag below where it is stretched tight at the top. Make the first cut perpendicular to the bag to avoid splitting up the entire length of the bag and exposing the grain.

Step 7: Clean up

Site clean-up is vital for success. Spilt piles of grain and leftover small bags of grain provide an ideal harbour for insects to live and breed. It’s crucial to clean grain residues from machinery used for grain handling to prevent reinfestation with insects or pests before the next season.

(Sourced from GRDC Grain Storage Fact Sheet. To read more visit www.storedgrain.com.au)

Polytex Bunker Covers or Bunker Tarps can include tarp stenciling to your specifications

Polytex has a vast network of recommended & competent carriers Australia wide.

Polytex uses only first quality industrial fabrics for the manufacture of all products; well-known brands including Canvacon, Tarpee & Landmark variations

Access our calculator to get a comprehensive guide to planning and designing your grain storage.